Industry knowledge extension of this categor

AS one of the most professional warehouse equipment manufacturers in China, UN Forklift provides a wide range of warehouse equipment, and we have exported them to more than 70 countries. Currently we have reach truck, double reach truck, VNA truck, pallet stacker, pallet truck, and they are available in lead acid battery and lithium battery, they are energy saving and environmental friendly.

Started from 1978, Zhejiang UN Forklift Co., Ltd. is a professional material handling equipment manufacturer and OEM factory in China integrating R&D, production, sales and service. UN Forklift produces various types of forklifts, includes IC forklift: diesel forklift, LPG/Gasoline forklift, rough terrain forklift; 4-wheel & 3-wheel electric forklift with lead acid battery and lithium ion battery; and many kinds of warehouse equipment. UN forklift will continue to produce forklifts features more energy saving, smarter and higher cost effective!

What is Warehouse Equipment

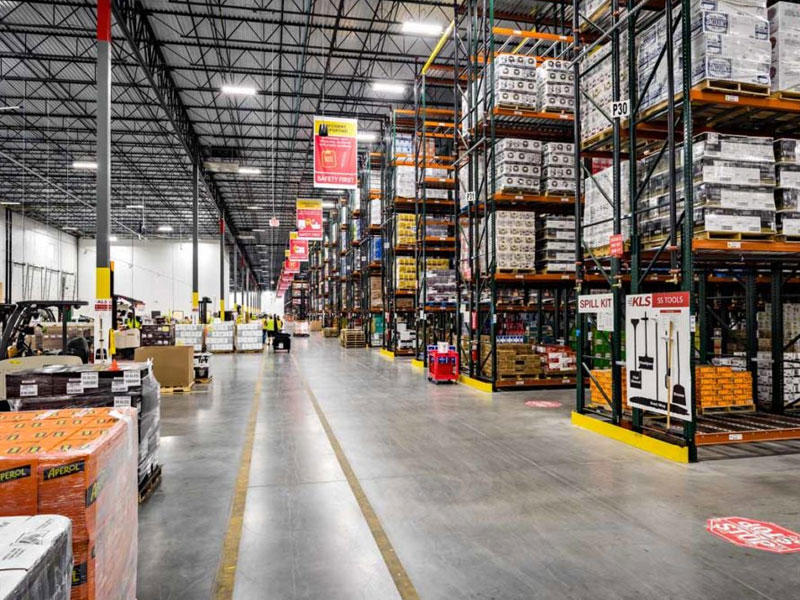

Warehouse equipment refers to the tools and machinery used to efficiently store, organize, and move materials within a warehouse. These tools and machinery are designed to help companies streamline their operations and increase productivity. Some common examples of warehouse equipment include:

1.Pallet racks: These are used to store and organize pallets of goods.

2.Conveyors: These are used to move materials from one point to another within the warehouse.

3.Forklifts: These are used to lift and move heavy loads within the warehouse.

4.Shelving: These are used to store smaller items or items that don't fit on pallets.

5.Mezzanine: These are used to create additional storage space by adding a second level to the warehouse.

6.Automated Storage and Retrieval Systems (AS/RS): These are systems that use machines to automatically store and retrieve items in the warehouse, reducing the need for manual labor.

7.Automated Guided Vehicles (AGVs): AGV are a type of mobile robot that are guided by marked lines or wires on the floor or by vision, laser, or infrared sensors. They are used to transport materials, equipment, or to perform tasks like inspection, painting, and welding.

8.Barcode scanners: These are used to track inventory and ensure accuracy in warehouse operations.

Use of Warehouse Equipment

Warehouse equipment is used to increase efficiency and productivity within a warehouse by helping to store, organize, and move materials. The specific use of warehouse equipment may vary depending on the type of equipment and the warehouse operation, but here are a few examples:

1.Pallet racks: These are used to store and organize pallets of goods. They provide a compact and organized method of storing large quantities of items, allowing easy access to any specific product.

2.Conveyors: These are used to move materials from one point to another within the warehouse, such as from receiving area to storage or from storage to shipping. They help to automate the movement of goods and reduce the need for manual labor.

3.Forklifts: These are used to lift and move heavy loads within the warehouse, such as pallets of goods or large boxes. They are essential for moving products from one location to another and for loading and unloading trucks.

4.Shelving: These are used to store smaller items or items that don't fit on pallets. They provide a compact and organized method of storing a wide range of items, making them easily accessible.

5.Mezzanine: These are used to create additional storage space by adding a second level to the warehouse. They can help to increase storage capacity while maximizing the use of available space.

All these equipment have the goal of streamlining warehouse operations and increasing productivity. These equipment have different features and capabilities, which makes them suitable for different types of warehouse operations and environments.

-2.jpg?imageView2/2/format/jp2)