Safety Features of the Double Deep Reach Truck

Overview of Double Deep Reach Trucks

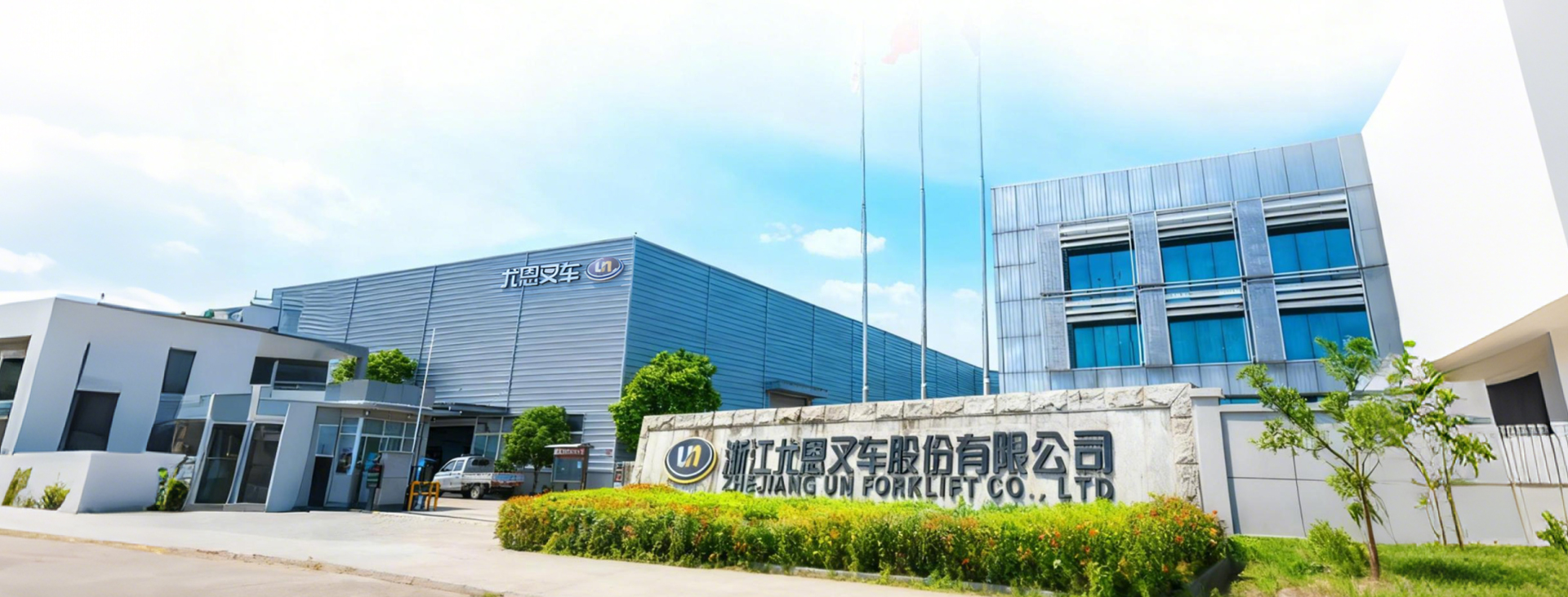

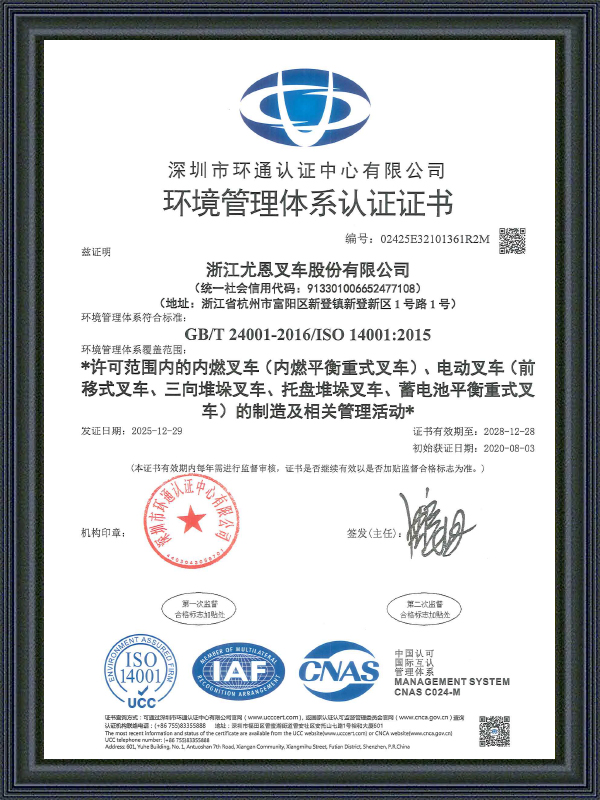

The double deep reach truck is a specialized type of warehouse equipment designed for high-density storage environments. Its extended reach capability allows operators to access pallets stored two positions deep, maximizing storage efficiency while minimizing aisle space requirements. Zhejiang UN Forklift Co., Ltd., with decades of experience in material handling equipment, ensures that all double deep reach trucks are engineered with energy-saving, high-efficiency, and safety-focused designs to meet global warehouse demands.

Importance of Tire Design in Stability

Anti-skid tires are critical for maintaining stability and safe operation of the double deep reach truck. UN Forklift incorporates durable tires with optimized tread patterns to enhance traction on warehouse floors. This design reduces the risk of slippage, especially in environments with smooth, polished surfaces or slight moisture. Anti-skid tires ensure operators can maneuver heavy loads safely without compromising control.

Automatic Deceleration Systems

Automatic deceleration systems are integrated into UN Forklift’s double deep reach trucks to manage speed during lifting, lowering, and turning. The system adjusts the truck’s velocity in response to load weight, mast position, and operator input. By automatically reducing speed during sharp turns or high-lift operations, the deceleration system minimizes the risk of tipping or load loss, improving overall operational safety.

Combined Safety Mechanisms

Safety on the double deep reach truck is achieved through the combination of anti-skid tires, automatic deceleration, and other protective systems such as load backrests, electronic interlocks, and emergency stop mechanisms. These features work together to maintain stability, prevent accidents, and provide operators with confidence when handling high-density pallets.

| Safety Feature | Function | Impact on Operation |

| Anti-Skid Tires | Enhance traction on warehouse floors | Reduce slippage and improve maneuverability |

| Automatic Deceleration | Control speed during lifting and turning | Maintain stability and reduce tipping risk |

| Load Backrest | Support for extended pallets | Prevent load from falling backward |

| Electronic Interlocks | Restrict unsafe operations | Enhance operator control and safety |

| Emergency Stop | Immediate shutdown of truck functions | Reduce potential accidents in emergencies |

Inspection and Maintenance of Safety Features

Regular inspection and maintenance of anti-skid tires and automatic deceleration systems are essential to ensure long-term reliability. UN Forklift provides maintenance schedules and global after-sales support, covering Europe, North America, South America, Africa, and Asia. Routine checks include tire tread depth, hydraulic and braking system function, and calibration of deceleration sensors to maintain optimal performance.

Ergonomic and Operational Considerations

The design of double deep reach trucks also considers operator ergonomics to complement safety systems. Adjustable seating, intuitive control panels, and clear visibility of pallets help reduce operator fatigue and errors. Integrating these ergonomic features with anti-skid tires and automatic deceleration ensures that high-density material handling is both efficient and safe.

Energy Efficiency and Environmental Impact

UN Forklift integrates energy-efficient components into the double deep reach truck, including optimized electric drives and regenerative braking. The automatic deceleration system contributes to energy saving by controlling speed without excessive power consumption. These features align with UN’s commitment to environmental protection while maintaining operational efficiency.

Application in Modern Warehouses

Double deep reach trucks are particularly valuable in warehouses where space is at a premium. The combination of anti-skid tires, automatic deceleration, and other safety mechanisms allows operators to move heavy pallets efficiently while minimizing risk. UN Forklift’s global sales and service network ensures that companies using this warehouse equipment have access to technical support, spare parts, and training to maximize the safe and efficient use of the trucks.

| Warehouse Condition | Recommended Safety Feature | Benefit |

| Smooth Concrete Floor | Anti-Skid Tires | Enhanced traction and stability |

| High Stacking Areas | Automatic Deceleration | Reduced tipping risk during lifts |

| Extended Pallets | Load Backrest | Prevents load displacement |

| Frequent Turning | Electronic Interlocks | Controlled and safe maneuvering |

| Emergency Situations | Emergency Stop | Immediate cessation of operations |

FAQ

Q: How does the double deep reach truck enhance storage efficiency in high-density warehouses?

A: UN Forklift’s double deep reach truck allows operators to access pallets stored two positions deep, reducing aisle space requirements and maximizing storage capacity. This capability is particularly valuable in warehouses with limited floor area, enabling more efficient use of available space while maintaining safe handling practices.

Q: What safety systems are integrated into the double deep reach truck?

A: The double deep reach truck incorporates features such as anti-skid tires, automatic deceleration, load backrests, electronic interlocks, and emergency stop functions. These systems work together to ensure stability, prevent accidents, and provide operators with greater control during high-density material handling operations.

Q: How does UN Forklift support maintenance for double deep reach trucks?

A: UN Forklift offers a global service network across Europe, North America, South America, Africa, and Asia. This network provides technical guidance, spare parts, routine inspection schedules, and maintenance support to ensure that double deep reach trucks remain reliable, safe, and operationally efficient throughout their lifecycle.

Q: How does the truck handle heavy or uneven loads?

A: The double deep reach truck is designed with reinforced frames, stable mast structures, and precise lifting mechanisms. These design elements allow it to handle varying load weights safely, maintain balance during transport, and reduce the risk of tipping or load displacement in both indoor and outdoor environments.

Q: What role does operator ergonomics play in the design of the double deep reach truck?

A: Operator comfort and ergonomics are incorporated through adjustable seats, clear visibility of pallets, intuitive control panels, and easy access to safety features. These design considerations reduce fatigue, enhance precision, and support safe operation over extended shifts, especially in high-density storage environments.

Q: How does the double deep reach truck contribute to energy efficiency in warehouse operations?

A: UN Forklift integrates energy-saving components such as optimized electric drives, regenerative braking, and automatic deceleration systems in its double deep reach trucks. These features reduce energy consumption while maintaining operational performance, aligning with UN’s focus on environmental protection and efficiency.

Q: Can the double deep reach truck be customized for different warehouse layouts?

A: Yes, UN Forklift offers configurations and options to suit varying aisle widths, floor conditions, and stacking heights. This flexibility allows operators to optimize the truck’s performance for their specific warehouse requirements, ensuring safe, efficient, and high-density material handling.