Efficiency and Suitability of Pallet Stackers for High-Frequency Operations

Overview of Pallet Stackers

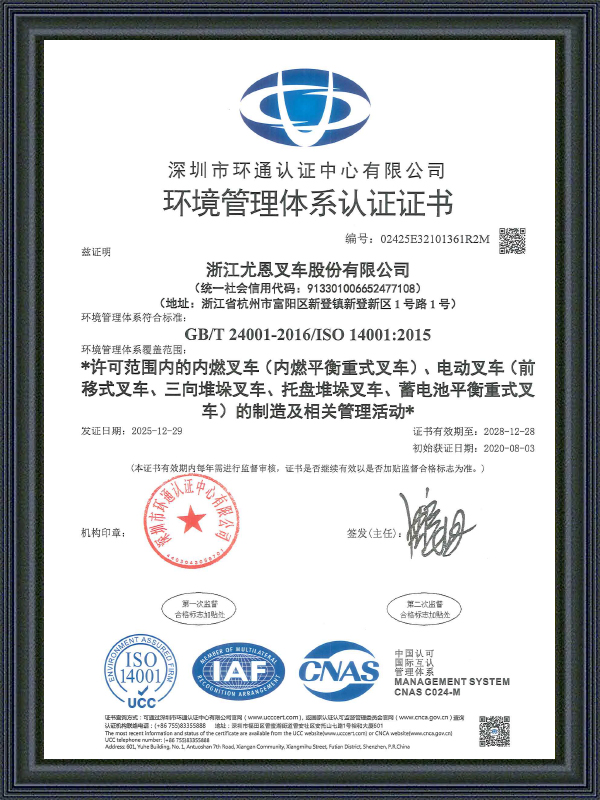

Pallet stackers are versatile warehouse equipment designed to lift, lower, and transport palletized goods. Zhejiang UN Forklift Co., Ltd. combines decades of experience in research, development, production, and service to design pallet stackers that prioritize energy efficiency, operational safety, and high performance. These machines are widely used in warehouses, production facilities, and logistics centers where reliable handling of pallets is essential.

Design Features Supporting High-Frequency Operations

High-frequency handling and picking operations require equipment that can sustain repeated lifting and movement without compromising performance. UN Forklift pallet stackers are engineered with robust hydraulic systems, reinforced frames, and durable lifting chains to handle continuous operations. The design ensures that operators can perform frequent lifts, lowering, and transportation of pallets efficiently while maintaining stability and control.

Ergonomic Considerations for Operators

Ergonomic design plays a key role in high-frequency operations. UN Forklift pallet stackers feature adjustable handles, intuitive control layouts, and operator-friendly interfaces. These considerations reduce fatigue during repeated movements and provide greater precision when positioning pallets. Operator comfort and ease of use directly contribute to maintaining efficiency during long shifts and repetitive handling tasks.

Speed and Maneuverability in Narrow Aisles

Pallet stackers are often used in narrow warehouse aisles where maneuverability is crucial. UN Forklift pallet stackers are compact, with optimized wheelbases and turning radii, allowing operators to navigate tight spaces efficiently. Integrated speed control and smooth lifting mechanisms enable precise placement of pallets even under frequent handling conditions, minimizing the risk of collisions or load displacement.

Durability and Maintenance

High-frequency operations place stress on mechanical and hydraulic components. UN Forklift pallet stackers are built with high-quality materials and components to withstand repeated use. Regular maintenance, including lubrication of moving parts, inspection of hydraulic systems, and checking tire or wheel conditions, is recommended to ensure long-term reliability. The company’s global service network supports operators with spare parts, technical guidance, and routine inspection schedules.

| Component | Function | Benefit for High-Frequency Operations |

| Hydraulic Lifting System | Raise and lower pallets smoothly | Supports repeated lifts without performance loss |

| Reinforced Frame | Provide structural stability | Ensures safety and reduces deformation under heavy loads |

| Ergonomic Handle | Operator-friendly control | Reduces fatigue during frequent handling |

| Compact Wheelbase | Enhances maneuverability | Enables operation in narrow aisles efficiently |

| Durable Wheels | Support repeated movement | Maintains smooth transportation over time |

Integration with Warehouse Workflow

Pallet stackers are particularly useful in environments where goods are frequently moved between storage areas and picking zones. UN Forklift designs its stackers to integrate seamlessly into automated or semi-automated workflows. The equipment allows for rapid pallet handling, accurate positioning, and safe stacking, which is essential for warehouses that require high throughput and minimal downtime.

Energy Efficiency in Repeated Use

Repeated lifting and transportation of pallets can consume significant energy. UN Forklift pallet stackers are designed with energy-efficient components, including low-resistance hydraulic circuits and optimized electric drives. These features reduce energy consumption while maintaining consistent lifting performance, contributing to both operational cost savings and environmental sustainability.

Application in Modern Warehouses

Modern warehouses with high-frequency picking and handling operations benefit from the combination of maneuverability, durability, ergonomic design, and safety features in UN Forklift pallet stackers. These machines ensure that operators can manage high volumes of goods efficiently and safely. With the support of UN Forklift’s global service network, warehouses can maintain operational continuity and reliability, ensuring smooth logistics and storage operations across various regions.

| Warehouse Condition | Recommended Feature | Operational Benefit |

| Narrow Aisles | Compact Wheelbase | Improved maneuverability and faster pallet handling |

| High Handling Frequency | Durable Hydraulic System | Reliable operation for repeated lifts |

| Long Shifts | Ergonomic Controls | Reduced operator fatigue and improved efficiency |

| Heavy Pallets | Reinforced Frame | Maintains structural integrity and safety |

| Energy-Conscious Operations | Optimized Drive Systems | Lower energy consumption during continuous use |

FAQ

Q: How does the pallet stacker support efficiency in high-frequency warehouse operations?

A: UN Forklift’s pallet stackers are designed with smooth hydraulic lifting systems and ergonomic controls, allowing operators to handle pallets quickly and accurately. These features reduce cycle time for repetitive lifting and transportation tasks, improving workflow efficiency in warehouses with high-frequency operations.

Q: What safety mechanisms are incorporated in pallet stackers?

A: Pallet stackers from UN Forklift include safety features such as load backrests, anti-skid wheels, and emergency stop controls. These mechanisms help prevent accidents, ensure stability during lifting, and provide operators with confidence when moving heavy or high-stacked pallets.

Q: How do pallet stackers handle different load weights and sizes?

A: UN Forklift designs pallet stackers with reinforced frames and adaptable forks to accommodate various pallet sizes and weights. The hydraulic system maintains smooth lifting regardless of load variations, ensuring safe and consistent operation across different warehouse needs.

Q: What makes pallet stackers suitable for narrow aisle environments?

A: The compact design and optimized wheelbase of UN Forklift pallet stackers allow operators to maneuver efficiently in narrow aisles. Precision steering and small turning radii enable accurate pallet placement without damaging racks or other equipment.

Q: How does operator ergonomics enhance pallet stacker performance?

A: Ergonomic handles, intuitive control layouts, and adjustable components reduce operator fatigue and improve precision. This is particularly important during long shifts or continuous operations, enabling consistent performance while maintaining operator comfort.

Q: What maintenance considerations are important for pallet stackers?

A: Regular inspection of hydraulic systems, wheels, and lifting chains is recommended to ensure reliability. UN Forklift provides a global service network offering technical support, spare parts, and maintenance guidance to keep pallet stackers in optimal condition for ongoing warehouse operations.

Q: Can pallet stackers contribute to energy-efficient warehouse operations?

A: Yes, UN Forklift pallet stackers are equipped with energy-saving hydraulic components and optimized drive systems. These features reduce energy consumption during frequent lifting and transport tasks, aligning with the company’s focus on environmental protection and operational efficiency.