Are Three Wheel Electric 1.3T-2.0T Models Suitable for Narrow Warehouses or High-Density Shelving?

Design Characteristics of Three-Wheel Electric Forklifts

The structural configuration of a forklift plays a central role in determining its maneuverability within confined spaces. The three wheel electric 1.3T-2.0T series is specifically designed with a compact chassis and rear-wheel steering system that enables a smaller turning radius compared to many four-wheel models. This structural arrangement allows the forklift to pivot efficiently around tight corners, making it particularly relevant for warehouses where aisle widths are limited and storage density is high.

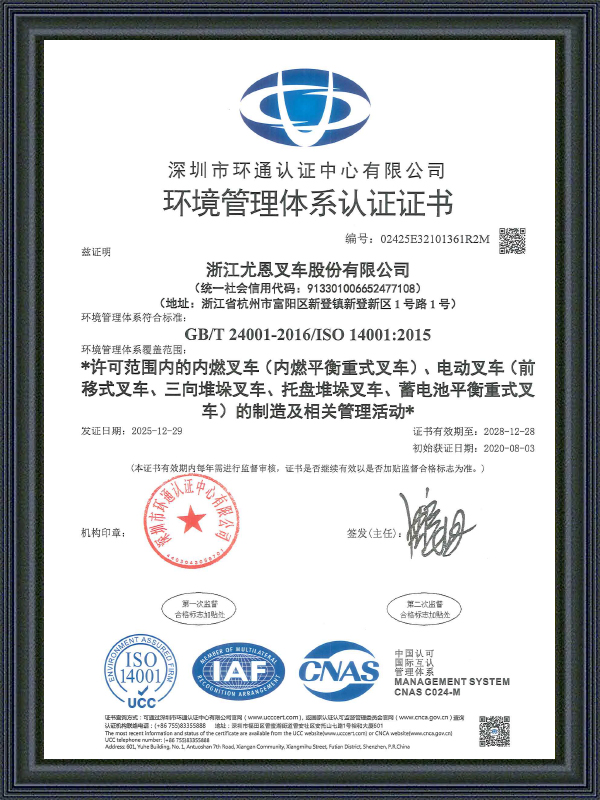

Zhejiang UN Forklift Co., Ltd., founded in 1978, integrates research and development, manufacturing, and testing within its 53,400 square meter facility. With an annual production capacity of 15,000 units, the company applies systematic engineering evaluation to ensure that each three wheel electric 1.3T-2.0T unit aligns with its design philosophy of energy saving, environmental protection, high efficiency, and safety.

Maneuverability in Narrow Aisle Environments

In narrow warehouse layouts, aisle width often determines equipment selection. The three wheel electric 1.3T-2.0T configuration allows a tighter turning radius due to its single rear steering wheel and compact wheelbase. This design enables operators to perform 90-degree stacking maneuvers with reduced repositioning. When navigating between high-density shelving systems, efficient steering response minimizes unnecessary movement and supports smoother pallet handling.

Rear-wheel steering enhances pivot control by allowing the rear of the forklift to swing in alignment with steering input. While this improves maneuverability, it also requires operator awareness, as the rear counterweight area follows a different path compared to front-wheel steering models. Proper training ensures stable and controlled movement within narrow aisles.

Load Capacity and Stability Considerations

The three wheel electric 1.3T-2.0T range is generally suited for light to medium-duty material handling. In high-density shelving environments, loads are often standardized pallets or cartons that fall within this capacity range. Stability in such applications depends on correct load positioning, proper mast alignment, and appropriate travel speed during turning.

Although three-wheel forklifts provide high maneuverability, their stability triangle differs from that of four-wheel models. Engineers compensate for this by optimizing battery placement and chassis weight distribution. In electric models, the battery pack is positioned low within the frame, lowering the center of gravity and contributing to balanced handling.

| Feature | Impact in Narrow Warehouses |

| Compact Wheelbase | Reduces turning radius |

| Rear-Wheel Steering | Improves pivot control |

| Low Battery Placement | Enhances stability |

| Rated Capacity 1.3T-2.0T | Suitable for standard pallet loads |

Performance in High-Density Shelving Systems

High-density shelving systems often require precise stacking at various lifting heights. The mast design and lifting mechanism of the three wheel electric 1.3T-2.0T models are engineered to provide controlled elevation and stable forward tilt angles. Smooth hydraulic response reduces load sway during vertical lifting, which is particularly important when stacking at upper rack levels.

Electric drive systems also contribute to controlled acceleration and deceleration. Unlike internal combustion units, electric forklifts offer consistent torque output, which supports gradual movement when approaching shelving units. This characteristic can reduce abrupt shifts that might otherwise affect load alignment.

Energy Efficiency in Confined Operations

Energy consumption is another factor influencing suitability for narrow warehouse operations. The three wheel electric 1.3T-2.0T series operates without direct exhaust emissions, making it suitable for indoor facilities with limited ventilation. Lithium or lead-acid battery configurations allow adaptation to different shift schedules, while opportunity charging can support continuous daily use.

UN Forklift integrates its energy-saving design principles into motor control systems and battery management strategies. By regulating power output during travel and lifting operations, the forklift maintains balanced energy usage across repetitive short-distance movements common in high-density storage environments.

Operational Safety in Tight Spaces

Safety considerations are particularly important in confined warehouse layouts. The compact design of the three wheel electric 1.3T-2.0T allows improved forward visibility, especially when equipped with optimized mast channel spacing. Clear sightlines assist operators in aligning forks accurately with pallet entry points.

Electronic speed limitation during sharp turns may be integrated to reduce lateral instability. Additionally, braking systems are calibrated to provide consistent stopping performance, even when maneuvering in narrow aisles with limited clearance.

| Operational Factor | Safety Relevance |

| Speed Control | Prevents abrupt lateral movement |

| Visibility Optimization | Supports precise pallet alignment |

| Braking Calibration | Maintains controlled stopping distance |

| Operator Training | Reduces handling errors in confined areas |

Comparative Perspective with Four-Wheel Models

While four-wheel forklifts generally offer broader stability under heavier loads, the three wheel electric 1.3T-2.0T demonstrates advantages in agility and spatial efficiency. In facilities where aisle width is restricted and load weights remain within moderate limits, the compact turning capability may outweigh the broader stability base of larger models.

The selection process depends on operational priorities. For example, if the warehouse emphasizes maximum storage density and narrow aisle design, the three-wheel configuration can align effectively with these structural constraints. Conversely, for heavier load handling at greater heights, other configurations may be considered.

Global Support and Application Adaptability

UN Forklift maintains sales and service partners across Europe, North America, South America, Africa, and Asia. This global network supports customers in selecting suitable configurations for local warehouse standards and safety regulations. Feedback from diverse markets contributes to continuous refinement of the three wheel electric 1.3T-2.0T design.

With integrated R&D and production capacity, Zhejiang UN Forklift Co., Ltd. evaluates chassis geometry, battery placement, and steering calibration to ensure compatibility with modern warehouse architecture. As storage systems continue to evolve toward higher density and narrower aisle configurations, maneuverability remains a central engineering focus in this product category.

FAQ

Q: How does the three wheel electric 1.3T-2.0T perform in narrow aisle operations?

A: The three wheel electric 1.3T-2.0T is designed with a compact chassis and rear-wheel steering that allows a tight turning radius. This makes it highly suitable for narrow warehouse aisles, enabling precise maneuvering and efficient stacking of goods without compromising stability.

Q: What factors contribute to the stability of the three wheel electric 1.3T-2.0T during turns?

A: Stability is influenced by battery placement, weight distribution, and chassis design. UN positions the battery low in the frame to lower the center of gravity, while the compact structure and optimized rear-wheel steering help maintain balance during sharp turns or when carrying light to medium loads.

Q: Can the three wheel electric 1.3T-2.0T handle high-density shelving operations effectively?

A: Yes, the forklift’s precise steering and controlled hydraulic lifting allow operators to navigate tight spaces and place loads accurately on high-density shelving. The ergonomic design and responsive control systems support safe operation in complex storage environments.

Q: How does UN ensure consistent quality in the production of three wheel electric 1.3T-2.0T models?

A: With a manufacturing facility covering 53,400 square meters and an annual production capacity of 15,000 units, UN integrates R&D, production, and testing processes internally. Each three wheel electric 1.3T-2.0T undergoes structural, electrical, and performance inspections before leaving the factory.

Q: What safety features are incorporated into the three wheel electric 1.3T-2.0T?

A: Safety systems include electronic speed control during turns, parking brake interlocks, load backrests, and stability monitoring. These features reduce the risk of tipping and help operators handle loads safely in confined or high-density storage areas.

Q: How energy-efficient is the three wheel electric 1.3T-2.0T for daily warehouse operations?

A: The electric drive system eliminates direct emissions and allows controlled energy consumption. Battery management systems optimize charging cycles, supporting multiple shifts and reducing downtime, in line with UN’s design focus on energy saving and environmental protection.

Q: How does UN support global operators of the three wheel electric 1.3T-2.0T?

A: UN Forklift has a worldwide network of sales and service partners across Europe, North America, South America, Africa, and Asia. This network provides maintenance guidance, spare parts supply, and technical consultation, ensuring operational continuity in diverse environments.

Q: What considerations should be made when choosing a specific model within the three wheel electric 1.3T-2.0T range?

A: Operators should evaluate load requirements, aisle width, lifting height, shift duration, and charging infrastructure. UN’s integrated production and R&D capabilities allow customization to match operational demands while maintaining high efficiency and safety standards.